Tungsten Carbide Mold

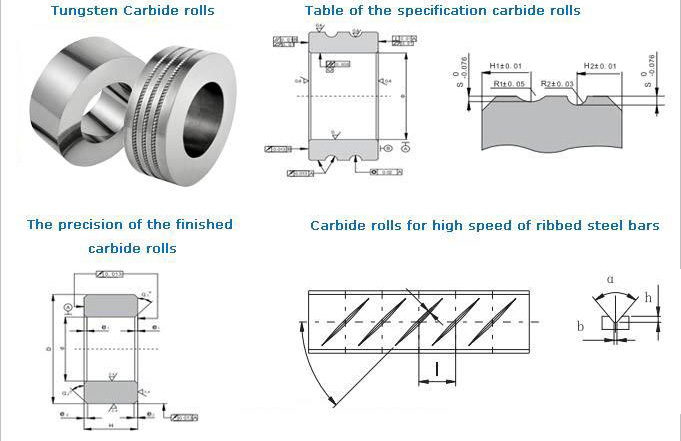

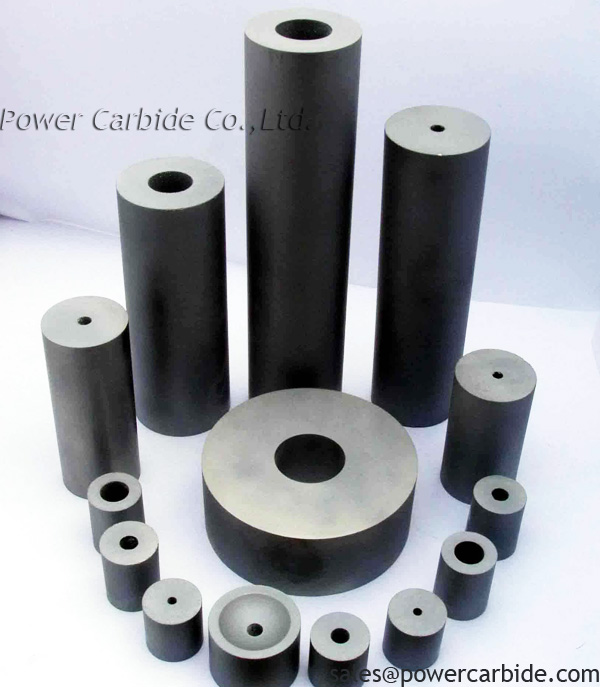

Tungsten Carbide Mill Rollers

- Application: For the manufacture of wire, bars and tubes used in Rolling Mills

- Features of carbide:Highest wear resistance, extreme hardness, high strength and bear high termperture

- Advantages: tool life 50 times longer than steel rolls

- Product description: We produce tungsten carbide mill rollers with the highest wear resistance for the wire, rods, pipe, tubes rolling used in high speed rolling mills, wire rods rolling mills etc.

And tungsten carbide rollers can be repaired repeatedly, and greatly reduces the production cost, significantly improves the efficiency.

Some standard sizes of tungsten carbide mill rollers

Size

Dimension(mm)

Diameter

Bore

Height

125*82*15

125.0

82.0

>=15

140.8*90*15

140.8

90.0

>=15

145*95*15

145.0

95.0

>=15

145.8*90*15

145.0

90.0

>=15

150*90*15

150.0

90.0

>=15

150*95*15

150.0

95.0

>=15

180*125*18

180.0

125.0

>=18

TAG:Carbide Circular Blades,Tungsten Carbide Inserts,Tungsten Carbide Mold,Carbide Customized Part,Carbide Tipped Work Rest Blade

Categories

- Solid Carbide Wood Cutters

- Precision Balls & Seats

- Carbide Circular Blades

- Carbide Rods & Endmills

- Precision Blades

- Fiber Cutter Blades

- Tungsten Carbide Inserts

- Carbide Strip & Plate

- Carbide Saw Tips & Blades

- Tungsten Carbide Mold

- Carbide Mining Tool

- Carbide Customized Part

- Carbide Tipped Work Rest Blade

Latest News

- Pure Tungsten Rods2017-10-19

- Tungsten Carbide Bars for Vsi Crusher2017-10-19

- PCD/CBN Indexable inserts with Tungsten Carbide Substrate2017-10-19

Contact: Andy

Phone: 0086-0731-22282989

Tel: 0086-0731-22282989

E-mail: sales@powercarbide.com

Add: Zhuzhou, Hunan, China

PowerCarbide

PowerCarbide Power Carbide

Power Carbide