Carbide Customized Part

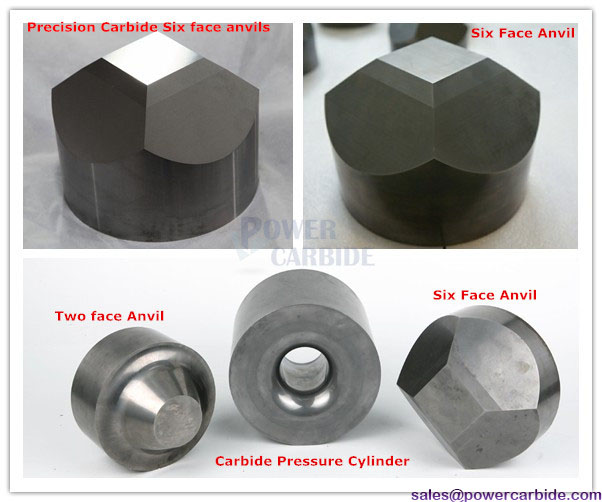

Tungsten Carbide Anvils

- Range: 6 facet carbide anvils, 2 facet carbide anvils, customized sizes anvils

- Application: For the manufacturing of synthetic diamond

- Advantage: High wear resistance, good toughness, high strength, thermal stability,precision finish

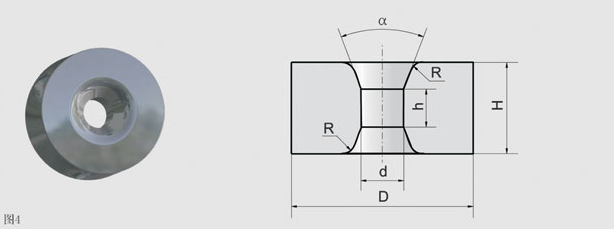

- Product description: We manufacture tungsten carbide anvils with types103, 110, 128, 160, 175 for Cubic Press for synthetic diamond, bearing high tempreture and high pressure very well.

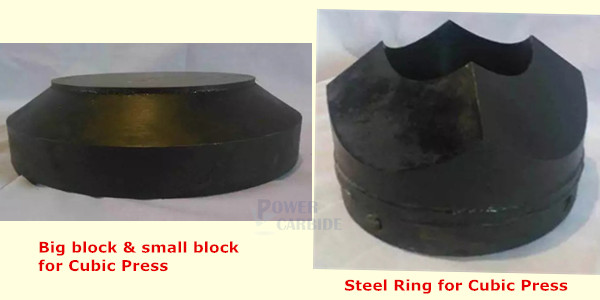

The taper on the anvil should be the same as that of a steel ring. The contact surface is ˃90%. The press fitting height should also be reasonable. Under cM27mm, the press fitting height is 8-10mm, and above cM27mm, the press fitting height is 10-12mm. There should be no point contact between the anvil and the spacer blocks to avoid stress concentration.

The machining precision of the steel ring and spacer blocks should meet all requirements. The smooth finish of the inner wall of the steel ring must achieve Ra1.6. The roundness and taper should conform to the tolerances of the form and position of the anvil. The depth of parallelism of large and small spacer blocks is ˂0.02mm. The hardness is moderate. Pyrophyllite calcination temperature and time should be moderate, in order to prevent blowouts caused by poor pressure carrying performance pressure and a high moisture rate. The surface of the conductive steel ring is rust resistant, and the edge has no cracks. There is no discoloration phenomenon, even after baking. Please pay attention to moisture resistant storage.

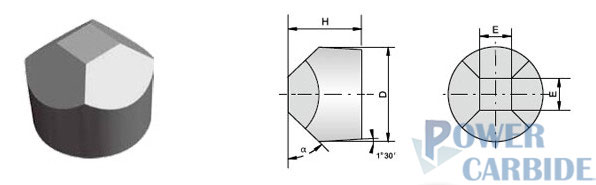

6-facet tungsten carbide anvils

|

Series |

D |

E |

H |

F |

β |

|

Φ103 |

103~105.0 |

32.5 |

76.0 |

12.5 |

41° |

|

103~105.0 |

32.5 |

83.0 |

11.5 |

41° |

|

|

103~105.0 |

32.5 |

77.0 |

12.5 |

41° |

|

|

103~105.0 |

33 |

77.0 |

12.5 |

41° |

|

|

103~105.0 |

33.5 |

77.0 |

12.5 |

41° |

|

|

Φ110 |

110.2 |

38.0 |

80.0 |

13 |

41° |

|

110.0~110.3 |

39.0 |

80.0 |

13 |

41.5° |

|

|

Φ114 |

114.6~114.9 |

39.5 |

82.5 |

13 |

41.5° |

|

115~115.5 |

36.5 |

82.5 |

12.5 |

41.5° |

|

|

115~115.4 |

38.0 |

82.5 |

12.5 |

41° |

|

|

115~115.1 |

38.0 |

82.5 |

14 |

41.5° |

|

|

115~115.6 |

39.5 |

82.5 |

13 |

41.5° |

|

|

115~115.3 |

39.0 |

82.5 |

13 |

41.5° |

|

|

115~115.9 |

40.0 |

82.5 |

13 |

41.5° |

|

|

115.2 |

40.0 |

84 |

13 |

41° |

|

|

115~115.2 |

41.0 |

82.5 |

13 |

42° |

|

|

115 |

41.0 |

82.5 |

13 |

41.5° |

|

|

Φ122 |

122.0~122.5 |

41.5 |

90 |

13 |

41.5° |

|

122.0~122.3 |

43 |

90 |

12 |

41° |

|

|

122.0~122.3 |

43 |

90 |

13 |

41° |

|

|

122.0~122.4 |

43 |

91 |

13 |

41.5° |

|

|

122.1 |

43.5 |

90 |

12 |

41° |

|

|

122.0~122.8 |

43.5 |

90 |

13 |

41.5° |

|

|

Φ127 |

127.0~127.5 |

43.5 |

95 |

13 |

41.5° |

|

127.0~127.8 |

43.5 |

93 |

13 |

41° |

|

|

127.0~127.3 |

44 |

93 |

13 |

41.5° |

|

|

127.0~127.4 |

46 |

95 |

13.5 |

41.5° |

|

|

127.0~127.6 |

47 |

95 |

12 |

41.5° |

|

|

127.0~127.2 |

47 |

93 |

13 |

41.5° |

|

|

127.0~127.8 |

47.5 |

95 |

13 |

42° |

|

|

127.0~127.1 |

48 |

94 |

12.5 |

41.5° |

|

|

127.0~127.5 |

48 |

9593 |

12 |

42.5° |

|

|

127.0~127.2 |

48.5 |

9496 |

12 |

42° |

|

|

Φ128 |

128.0 |

41.5 |

93 |

12.5 |

41° |

|

128.0 |

46 |

96 |

13 |

41.5° |

|

|

128.0~128.2 |

46 |

93 |

13.5 |

41.5° |

|

|

Φ142 |

142.0 |

49 |

102 |

15 |

41.5° |

|

Φ148 |

148.5 |

|

100 |

15 |

41° |

|

Φ160 |

106.0~160.3 |

|

110 |

15 |

41.5° |

|

Φ175 |

175.32 |

63.25 |

102 |

15 |

41° |

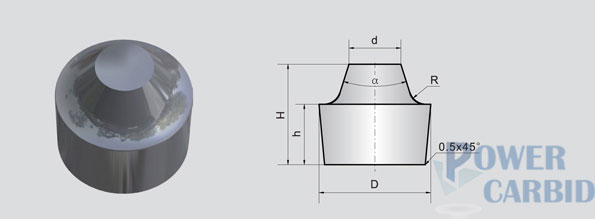

2-facet tungsten carbide anvils

Carbide Pressure Cylinder

TAG:Carbide Circular Blades,Tungsten Carbide Inserts,Tungsten Carbide Mold,Carbide Customized Part,Carbide Tipped Work Rest Blade

Categories

- Solid Carbide Wood Cutters

- Precision Balls & Seats

- Carbide Circular Blades

- Carbide Rods & Endmills

- Precision Blades

- Fiber Cutter Blades

- Tungsten Carbide Inserts

- Carbide Strip & Plate

- Carbide Saw Tips & Blades

- Tungsten Carbide Mold

- Carbide Mining Tool

- Carbide Customized Part

- Carbide Tipped Work Rest Blade

Latest News

- Pure Tungsten Rods2017-10-19

- Tungsten Carbide Bars for Vsi Crusher2017-10-19

- PCD/CBN Indexable inserts with Tungsten Carbide Substrate2017-10-19

Contact: Andy

Phone: 0086-0731-22282989

Tel: 0086-0731-22282989

E-mail: info@powercarbide.com

Add: Zhuzhou, Hunan, China

PowerCarbide

PowerCarbide Power Carbide

Power Carbide