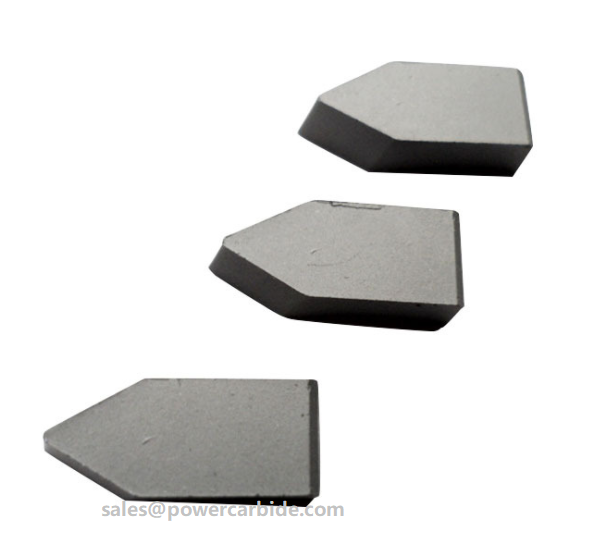

Tungsten Carbide Inserts

Tungsten Carbide Brazed Tips

- Main carbide grade: K10, K20, M10, M20, P10, P20, P30

- Made from High quality tungsten carbide material

- Product description: Tungsten carbide brazed tips are supplied in full types A, B, C, D,E, G for lathe turning tools.

Grade recommened for carbide brazed tips

|

Grade |

ISO Code |

Density |

Hardness |

T.R.S |

Applications recommended |

|

YG3 |

K05 |

15.10 |

92.0 |

1400 |

Suitable for finishing of cast iron and nonferrous metal. |

|

YG6X |

K10 |

14.95 |

91.5 |

1800 |

The finishing & semi-finishing of cast iron and nonferrous metals and also for the machining of manganese steel and hardening steel. |

|

YG6 |

K15 |

14.95 |

90.5 |

1900 |

Suitable for the roughing of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

|

YG8 |

K20 |

14.80 |

89.5 |

2200 |

|

|

YW1 |

M10 |

13.10 |

91.6 |

1600 |

Suitable for finishing and semi-finishing of stainless steel and conventional alloy steel. |

|

YW2 |

M20 |

13.00 |

90.6 |

1800 |

The grade can be used for the semi-finishing of stainless steel and low-alloy steel and it is mainly used for the machining of railway wheel hubs. |

|

YT15 |

P10 |

11.4 |

91.5 |

1600 |

Suitable for the finishing and semi-finishing for steel and cast steel with a moderate feed rate and rather high cutting speed. |

|

YT14 |

P20 |

11.6 |

90.8 |

1700 |

Suitable for the finishing and semi-finishing of steel and cast steel. |

|

YT5 |

P30 |

12.9 |

90.5 |

2200 |

Suitable for the heavy duty rough turning of and cast steel with a big feed rate at a medium and low speed under unfavorable working conditions. |

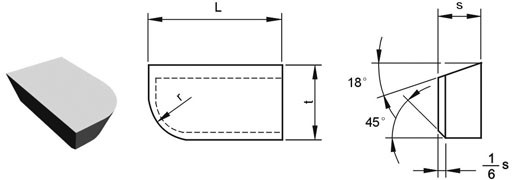

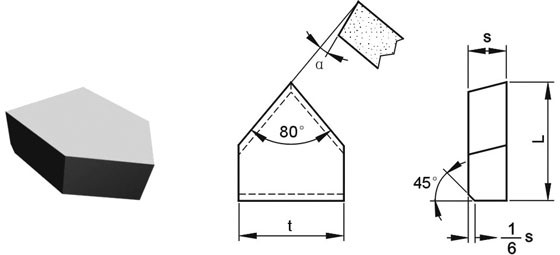

Carbide brazed tips Type A

Type

Dimension (mm)

L

t

s

r

A5

5.0

3.0

2.0

2.0

A6

6.0

4.0

2.5

2.5

A8

8.0

5.0

3.0

3.0

A10

10.0

6.0

4.0

4.0

A12

12.0

8.0

5.0

5.0

A16

16.0

10.0

6.0

6.0

A20

20.0

12.0

7.0

7.0

A25

25.0

14.0

8.0

8.0

A32

32.0

18.0

10.0

10.0

A40

40.0

22.0

12.0

12.0

A50

50.0

25.0

14.0

14.0

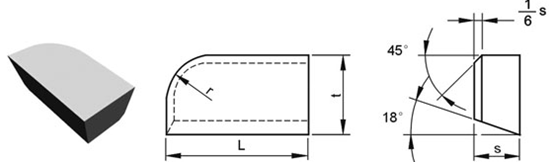

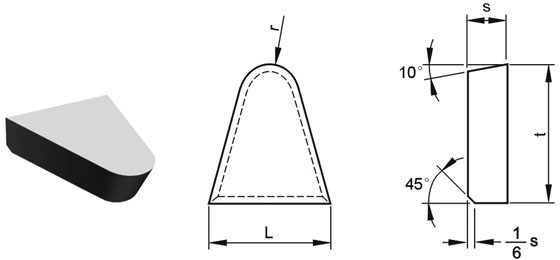

Carbide brazed tips Type B

Type

Dimension (mm)

L

t

s

r

B5

5.0

3.0

2.0

2.0

B6

6.0

4.0

2.5

2.5

B8

8.0

5.0

3.0

3.0

B10

10.0

6.0

4.0

4.0

B12

12.0

8.0

5.0

5.0

B16

16.0

10.0

6.0

6.0

B20

20.0

12.0

7.0

7.0

B25

25.0

14.0

8.0

8.0

B32

32.0

18.0

10.0

10.0

B40

40.0

22.0

12.0

12.0

B50

50.0

25.0

14.0

14.0

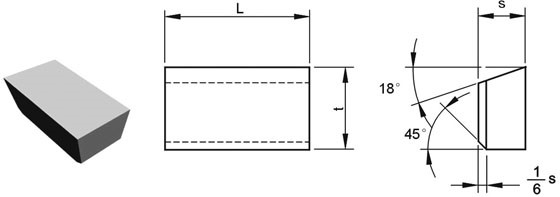

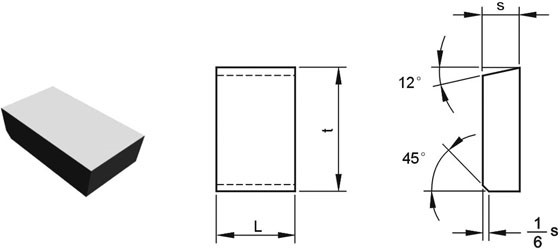

Carbide brazed tips Type C

Type

Dimension (mm)

L

t

s

r

C5

5.0

3.0

2.0

C5

C6

6.0

4.0

2.5

C6

C8

8.0

5.0

3.0

C8

C10

10.0

6.0

4.0

C10

C12

12.0

8.0

5.0

C12

C16

16.0

10.0

6.0

C16

C20

20.0

12.0

7.0

C20

C25

25.0

14.0

8.0

C25

C32

32.0

18.0

10.0

C32

C40

40.0

22.0

12.0

C40

C50

50.0

25.0

14.0

C50

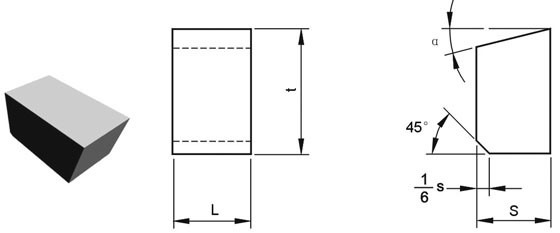

Carbide brazed tips Type D

Type

Dimension (mm)

L

t

s

r

ɑ

D3

3.5

8.0

3.0

/

D3

D4

4.5

10.0

4.0

14°

D4

D5

5.5

12.0

5.0

14°

D5

D6

6.5

14.0

6.0

14°

D6

D8

8.6

16.0

8.0

14°

D8

D10

10.5

18.0

10.0

14°

D10

D12

12.5

20.0

12.0

14°

D12

Carbide brazed tips Type E

Type

Dimension (mm)

L

t

s

r

ɑ

E4

10.0

4.0

2.5

/

E4

E5

12.0

5.0

3.0

/

E5

E6

14.0

6.0

3.5

/

E6

E8

16.0

8.0

4.0

9°

E8

E10

18.0

10.0

5.0

9°

E10

E12

20.0

12.0

6.0

9°

E12

E16

22.0

16.0

7.0

9°

E16

E20

25.0

20.0

8.0

9°

E20

E25

28.0

25.0

9.0

9°

E25

E32

32.0

32.0

10.0

9°

E32

Carbide brazed tips Type G

Type

Dimension (mm)

L

t

s

r

G8

8.0

12.0

4.0

1.0

G10

10.0

14.0

4.0

1.5

G12

12.0

17.0

5.0

2.5

G16

16.0

20.0

6.0

3.5

G20

20.0

24.0

6.0

4.5

G25

25.0

28.0

8.0

6.0

G30

30.0

34.0

10.0

8.0

Carbide brazed tips Type K

Type

Dimension (mm)

L

t

s

K2

2.5

15.0

4.0

K3

3.5

15.0

4.0

K4

4.5

15.0

4.0

K5

5.5

15.0

4.0

K6

6.5

15.0

4.0

K7

7.5

15.0

4.0

K8

8.5

20.0

6.0

K9

9.5

20.0

6.0

K10

10.5

20.0

6.0

K12

12.5

20.0

6.0

Categories

- Solid Carbide Wood Cutters

- Precision Balls & Seats

- Carbide Circular Blades

- Carbide Rods & Endmills

- Precision Blades

- Fiber Cutter Blades

- Tungsten Carbide Inserts

- Carbide Strip & Plate

- Carbide Saw Tips & Blades

- Tungsten Carbide Mold

- Carbide Mining Tool

- Carbide Customized Part

- Carbide Tipped Work Rest Blade

Latest News

- Pure Tungsten Rods2017-10-19

- Tungsten Carbide Bars for Vsi Crusher2017-10-19

- PCD/CBN Indexable inserts with Tungsten Carbide Substrate2017-10-19

Contact Us

Contact: Andy

Phone: 0086-0731-22282989

Tel: 0086-0731-22282989

E-mail: sales@powercarbide.com

Add: Zhuzhou, Hunan, China

PowerCarbide

PowerCarbide Power Carbide

Power Carbide